Products

High-Quality Pressure Reactors, Hydrogenation & Polymerization Reactors

Duraclave

Why should you choose Duraclave?

This multipurpose

pressure reactor system is designed and engineered to use with

interchangeable glass pressure vessels. The duraclave has an

impact resistant protective shield at all sides of the system

for the operators safety. The glass reactors ensure high

resistance against acids, while allowing visual process control

and monitoring. Various low to high torque agitator magnetic

drives ensure efficient mixing and stirring low to high

viscosity process media as well as excellent heat transfer. The

customisable setup of the duraclave system allows changing or

upgrading for new tasks at any time. The vessels can be swapped

and cleaned effortlessly due to quick release clamp and lifting

lowering mechanism. A broad range of accessories for feeding of

liquids, solids, gas and others like catalyst baskets etc. are

available – contact us to design the right setup for your

specific requirement.

Typical Application :

- Hydrogenation reactor

- Polymerization reactor

- Synthesis reactor

- Catalyst testing / evaluation

- Catalytic reactor

- Crystallization

- Chemical research, synthesis

- Petrochemical research

- Zeolite synthesis

- Nanoparticle synthesis

- Corrosion testing autoclave

- Corrosion Measurement

- Upstream research Biomass research

- Biopolymer, Biorefinery, Biofuels research

Specifications :

- Nominal volume glass vessel ml: 250,500, 1000, 1500

- Working temperature °C: -20 to + 200

- Glass reactor made of borosilicate 3.3. Double jacket design with bottom drain valve.

- Operating overpressure glass reactor -1 bar or up to +10 bar

- Quick release: Jaw lock can be opened by hand directly below the chassis plate. The chassis plate keeps the reactor centred.

- O-ring seal Viton, Kalrez or EPDM lying in the autoclave vessel.

- Magnetic stirrer head with a torque of 20,40, 60 or 90 Ncm, connected to the laboratory drive via a flexible coupling.

- Agitator drive: IKA, Heidolph, Neuation, CAT etc.

- Output speed with ball bearing 0-1’300 rpm, with plain bearing 0-1’200 rpm.

- Pressure gauge chemical version

- Valve for gas supply

- Valve for pressure relief

- Valve with immersion tube for sampling and draining.

- Spring pressure safety valve, resp. HC bursting disc holder with bursting disc

- Immersion well with temperature sensor Pt100

- Stirring element: Gas flushing stirrer or other can be used.

- Heating: Double jacket for heat transfer oil

- 4-cornered base chassis, height adjustable via the four adjustable feet

- Lifting lowering device for vessel.

- Polycarbonate Protective sliding door.

Glass Pressure Vessels

The vessels of duraclave are made of high-quality borosilicate 3.3 glass acc. to ISO 3585, which is chemically and thermally highly resistant. Safety is important when working with glass vessels. The actual design pressure of duraclave glass vessels is much higher than the allowed working pressure and allows virtually risk-free operation.

- Vessel capacity: 250ml, 500 mL, 1 L and 1.5 L

- Vessel type: Double wall with bottom drain valve

- Operating pressure: Full vacuum to +10 bar

- Operating jacket pressure: Up to +0.5 bar

- Operating temperature:-20 °C to +200 °C

- Operating temperature:60 °C (double wall)

A magnetic stirrer coupling with M30x2 thread connection which can easily be screwed into reactor lid. The threaded permanent magnetic couplings provide a space-saving installation with their compact design to have good number of ports on the lid to add accessories. Ball bearings ensure rapid, easy replacement to facilitate maintenance and cleaning. Magnetic stirrer couplings are available in stainless steel, Hastelloy®, titanium, zirconium and other materials. Different torque levels and seals are offered on request.

- MGSC-40 Max Viscosity: 1500mPA (for 1000ml), Max torque: 40 Ncm

- MGSC-60 Max Viscosity: 6000mPA (for 3000ml), Max torque: 60 Ncm

- MGSC-90 Max Viscosity: 1000mPA (for 5000ml), Max torque: 90 Ncm

Stirrer

Different types and sizes of stirrer are possible based on the type and viscosity of the reaction mass. Available MOC: 1.4435, combination 1.4435/PTFE or 2.4602 other material are possible on request.

Our gas supplying stirrer has unique design. The gas input and saturation of the medium are faster than with conventional stirring systems. This results in considerably shorter reaction times in heterogeneous catalysis. This effect is further enhanced by a possible baffle. Hinder the 45-grid bevels of the propeller, a vacuum is created when the propeller rotates clockwise. This vacuum creates enormous suction power. Accordingly, the gas is quickly brought out of the gas chamber via the hollow shaft into the medium.

Process Equipment Accessories

Various process equipment accessories are possible to meet process specification requirement. Eg. control valves, metering valves, safety valves, fittings, regulators, tubes, hoses, sampling system, spargers, catalyst basket etc. contact us to choose the right accessories for your specific process requirement.

Reactor Automation

We can offer complete turnkey solution which includes automation for the reactor system (PC/HMI version.) and integration of third- party instruments i.e. sensors for process parameters, online analytical tools, mass flow controller, pressure controller, dosing pumps & heating cooling system etc. Talk to us to choose optimum degree of automation for duraclave.

DuraclaveTeeny & Mini Steel Reactor

This system is designed to allow the use of interchangeable pressure

vessels made from glass, steel, Hastelloy®, Teflon or any other

material. Safety features are designed to ensure that reactions are

performed safely under pressure.

In addition to ensuring high

resistance to acids, the glass pressure reactors also allow visual

control and monitoring of the process to ensure maximum efficiency.

DURACLAVE – Teeny Steel Reactor

Specification:

- Nominal glass volume 10 – 40 ml

- Temperature range – 20°C… + 200°C

- Pressure -1… + 10 bar (Glass vessel) -1… + 100 bar (Stainless steel vessel)

- Steel cover plate with 2 openings: 1/8” NPT for Swagelok / fitok fittings, rupture disk with holder, pressure gauge, needle valves

- Interchangeable reaction vessel: Glass, Steel, Haste alloy ( with optional PTFE insert

- Other MOC for reaction vessel also available on request

- Vessel holder with protective mesh for glass reactor

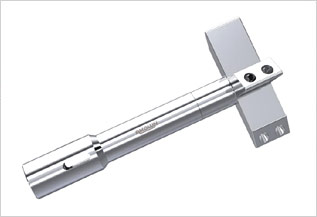

- Coupling nut

DURACLAVE – Mini Steel Reactor

Specification:

- Nominal glass volume 100 – 300 ml

- Temperature range – 20°C… + 200°C

- Pressure -1… + 10 bar (Glass vessel) -1… + 100 bar (Stainless steel vessel)

- Steel cover plate with 4 openings: 1/4” NPT for Swagelok / fitok fittings, rupture disk with holder, pressure gauge, needle valves, temperature sensors

- Interchangeable reaction vessel: Glass, Steel, Hastelloy ( with optional PTFE insert)

- Other MOC for reaction vessel also available on request

- Vessel holder with protective mesh for glass reactor

- Coupling nut

DURACLAVE – Mini Inert Reactor

Specification:

- Nominal glass volume 100 – 300 ml

- Temperature range – 20°C… + 150°C

- Pressure -1… + 10 bar (Glass vessel)

- PTFE cover plate with 4 openings: 1/4” NPT for Swagelok / fitok fittings, rupture disk with holder, pressure gauge, needle valves, temperature sensor

- Interchangeable reaction vessel: Glass

- Vessel holder with protective mesh

- Coupling nut