Products

Photochemical Reactor - UV Photo Reactor Manufacturer

UV IMMERSION LAMP

FOR INDUSTRIAL PHOTOCHEMISTRY

- Pilot Scale

- Production Scale

Light Not Heat or how well-thought-out system can be used for photochemistry in R&D and Production

Application Examples: Customised Lab Scale and Pilot Scale Loop Photoreactor System

In synthesis, photochemistry is the method of choice. UV light can

vastly speed up many chemical syntheses – or make them possible in

the first place. Unlike thermal excitation, light-induced reactions

frequently occur at room temperature and are less destructive.

Sensitive molecules remain intact, and there are fewer

by-products.

Our product and competence in preparative photochemistry and

photochemical environmental techniques.

We sell UV-radiation sources and standard photochemical reactors for

immediate use to perform various preparative tasks at laboratory and

pilot levels. UV-radiation sources and corresponding reactors may be

adapted and optimized for specific procedures. ATEX/ IECEx radiation

certification for 2.5 to 40 kW electrical power is available on

request.

In many countries, regulations already govern the testing for

photochemically induced degradation of pharmaceuticals and

cosmetics. Akown delivers appropriate photoreactors. For production

units, we sell entire systems of irradiation, where parts may be

taken from standard programs comprising a variety of dimensions and

types of radiation sources. We neither construct nor sell

photocatalytic reactors for production units, as this task remains

entirely within the domain of competence and responsibility of the

user. However, in cooperation with our partner UV-Technik

Speziallampen GmbH, we offer consulting services based on scientific

and technical expertise.

Furthermore, we offer the possibility to analyse the reactor

geometry of planned or existing production-scale photocatalytic

reactors utilizing professional flow-simulation and physical

radiation data to optimise photochemical processes.

(UVPI) Pilot Scale UV Immersion Lamp [Usually up to 2.5 kW]

Pilot photocatalytic reactors represent critical intermediate

steps in upscaling all laboratory reactors to an optimized and

well-operating production system. They may also be used to

produce limited amounts of chemical compounds. The UVPI

immersion lamp series has been developed to be retrofitted onto

existing vessels already available in the R&D lab. Furthermore,

optional universal reactors, skid-mounted on a mobile rack, are

available.

Applications:

- Technical process development

- Production of smaller amounts of chemical compounds (kg d-1)

Specification:

| Sr.No. | Name | Specification |

|---|---|---|

| 01 | UV lamp Type | Medium Pressure Mercury Vapour Lamp |

| 02 | Power | 1.2-5 kW |

| 03 | Max Arc Length | 1000 mm |

| 04 | Mounting Flange | DN 100/120/150 |

| 05 | Cladding Tube 1 MOC | Quartz (UV grade, with special composition) |

| 06 | Cladding Tube 2 MOC | Quartz (UV grade, with special composition), Borosilicate 3.3 |

| 07 | Max Immersion Length | 1200 mm |

| 08 | Water Inlet- Outlet Connections | DN 15 |

| 09 | N2 Inlet- Outlet Connections | 1⁄4 inch Swagelok tube fittings |

| 10 | Power Supply | Ballast VTPS Or Electronic Power supply controller EPSA 80 |

| 11 | Ex-Proof Version | Not Available |

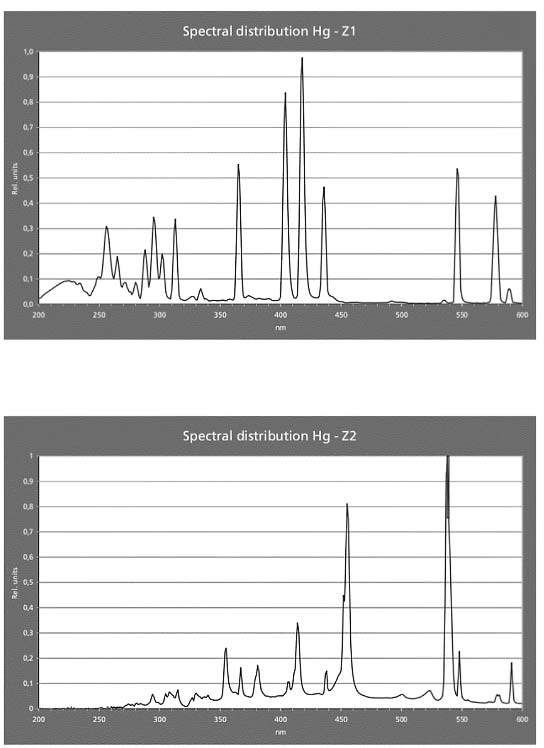

(UVPI SE) Production Scale UV Immersion Lamp [up to 40 kW]

The UVPI SE immersion lamp series represents the most powerful

immersion lamp system available and can be certified up to 40 kW

as per IECEx /ATEX directive for operation in hazardous areas.

Advantageous. Due to the modular construction, UVPI SE immersion

lamps are safe for future demands and can be adapted to changed

process parameters. In addition to the robust and secure design,

an optionally available third protection tube increases the

operational safety of the equipment when necessary.

Applications:

- Operation in the production scale

- Production of large amounts of chemical compounds (t d-1)

Specification:

| Sr.No. | Name | Specification |

|---|---|---|

| 01 | UV lamp Type | Medium Pressure Mercury Vapour Lamp |

| 02 | Power | 10 – 40 kW |

| 03 | Max Arc Length | 2600 mm |

| 04 | Mounting Flange | DN 250 PN 6/ PN 10 |

| 05 | Cladding Tube 1 MOC | Quartz (UV grade, with special composition) |

| 06 | Cladding Tube 2 MOC | Quartz (UV grade, with special composition) Borosilicate 3.3 |

| 07 | Cladding Tube 3 MOC (Optional) | Quartz (UV grade, with special composition), Borosilicate 3.3 |

| 08 | Max Immersion Length | 3000 mm |

| 09 | Water Inlet- Outlet Connections | DN 15/25 |

| 10 | N2 Inlet- Outlet Connections | Inlet: 1⁄4 inch Swagelok tube fittings Outlet: 1” Male NPT |

| 11 | Power Supply | Ballast VTPS Or Electronic Power supply controller EUV 5 |

| 12 | Ex-Proof Version | Available |

UV Medium Pressure Lamps

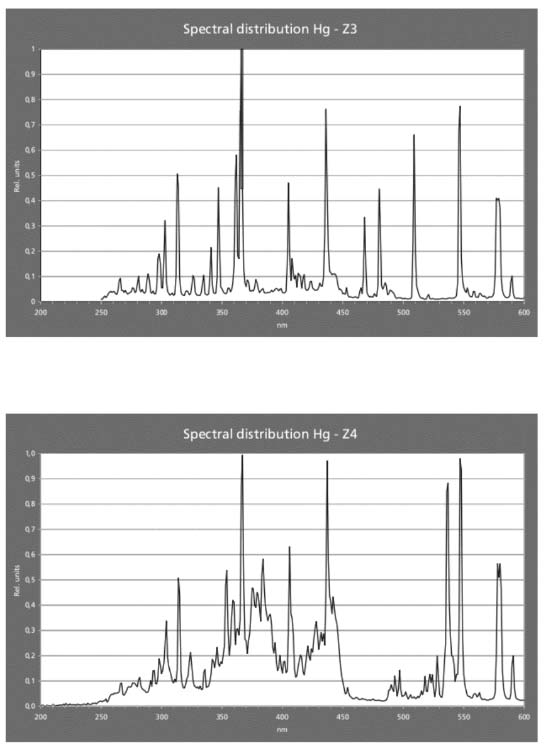

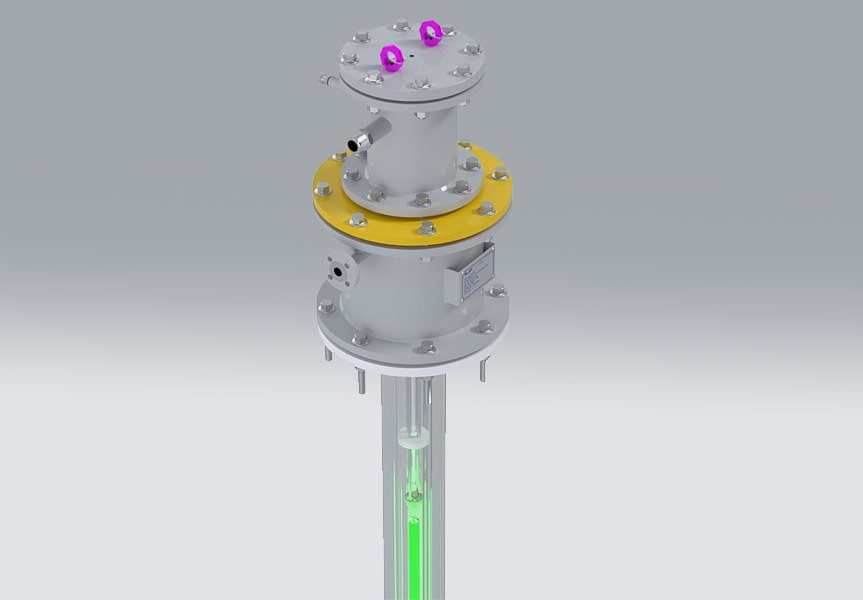

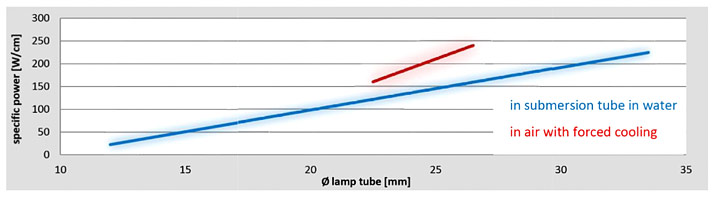

UV medium-pressure lamps are produced as linear lamps as standard. They consist of a sealed discharge tube made of quartz glass. The discharge vessel is filled with noble gases at a low pressure of several millibars. Moreover, UV medium pressure lamps contain a small amount of mercury and dopants, such as iron, gallium, or other elements. During operation, plasma is generated in the lamps, which emits radiation. As a rule, the plasma is excited by establishing a current flow between the electrodes, which are fused or crimped at both ends of the lamp. An electrode-free medium-pressure lamp can be stimulated to light using microwaves. By varying the length, the diameter (Graphic 1), and the filling, UV medium-pressure lamps can be influenced in their performance and adapted to different operating conditions.UV medium-pressure lamps must always be operated on a suitable ballast.

Graphic I: Typical specific performance of UV medium pressure lamps in W/cm light emitting length as a function of Ø

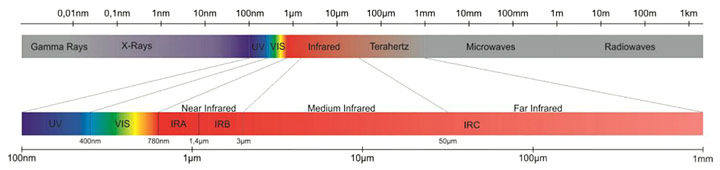

UV medium pressure lamps emit radiation from the UV range to the infrared (Graphic 2).

Graphic 2: Section from the electromagnetic spectrum with its typical classification

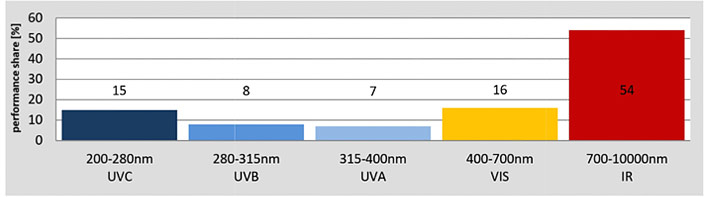

A considerable part of the radiation power of a medium pressure lamp

is in the infrared range (Graphic 3).

The lamps therefore

require cooling.

Graphic 3: Distribution of the power of a typical UV medium pressure lamp, Hg type across the spectrum

Automated Control System for UV Immersion Lamp

An automated control system for a UV immersion lamp consists of a Power Control Panel and an Operator Panel, which can be engineered depending on the degree of automation required and the scope for integrating instruments.

An electronic power supply enables stepless and accurate power regulation to the UV lamp. Furthermore, it provides features like measurement, control of process parameters, data logging and transfer, safety interlocks, and a user-friendly interface.